Key Features & Advantages

Why choose matrix hydraulic oil cleaning machine

The Matrix Hydraulic Oil Cleaning Machine is an innovative, semi-automated oil filtration system designed to remove contaminants, moisture, and sludge from various industrial oils. Engineered for optimal performance and longevity, this advanced system restores oils to like-new condition, significantly reducing maintenance costs and enhancing equipment reliability.

This multi-purpose filtration machine effectively cleans and purifies:

Additionally, it functions as an Oil Flushing Machine, making it a valuable asset for industries requiring precise oil quality control.

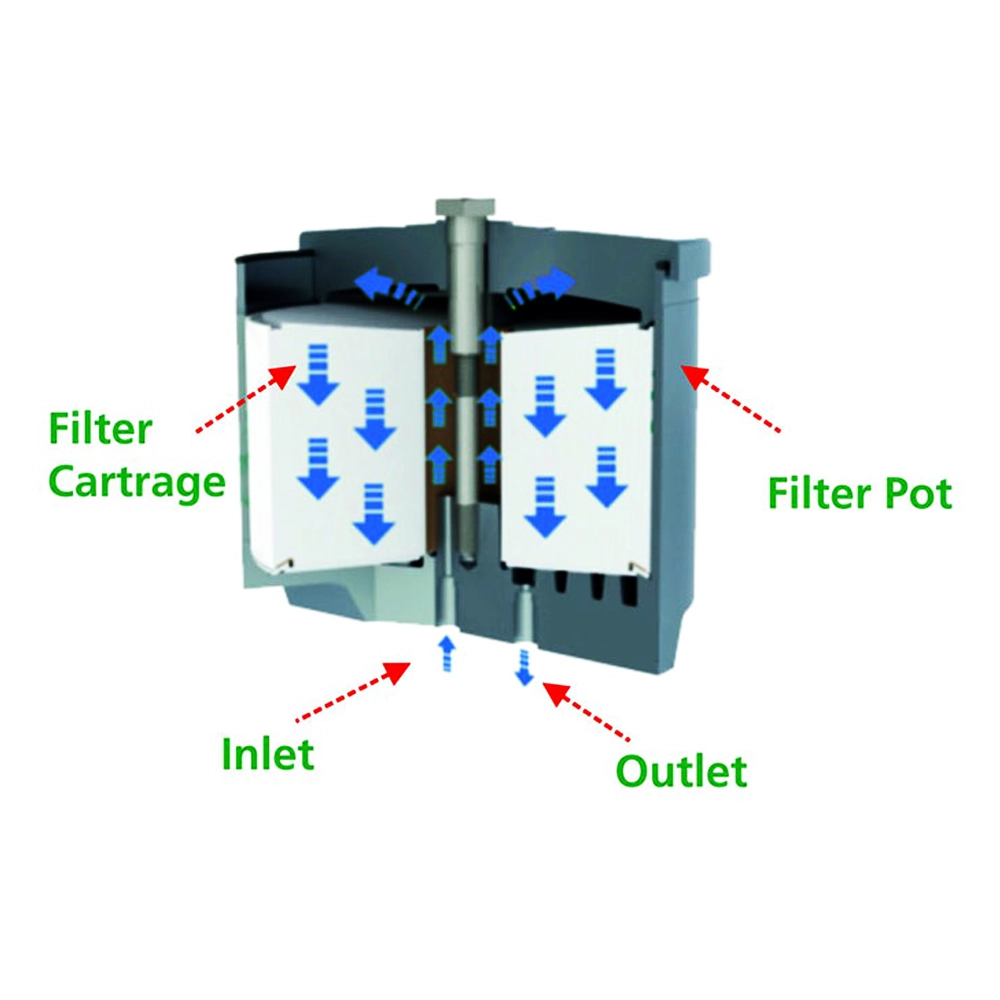

Matrix Hydraulic Oil Cleaning Machine utilizes a high-performance cellulose filter cartridge designed for continuous filtration. This cutting-edge system effectively absorbs free and dissolved water, removing up to 99.9% of contaminants through multi-layer filtration technology.

Matrix Filtration India Pvt Ltd is committed to delivering industry-leading oil cleaning solutions that enhance performance, sustainability, and cost efficiency.

Looking to extend oil life and improve reliability? Get in touch today!

| Model Number | Tank Capacity | Water Retention (Per Cartridge) |

Flow Rate (Per Hour) |

Electrical Motor | Dimensions (mm) |

|---|---|---|---|---|---|

| MFS/Single Filter | Up to 2,500 Liters | 1.25 kg | 600 LPH | HP 0.5, Volt 415, Phase 3, RPM 1450 | 900 x 500 x 500 |

| MFS/Double Filter | Up to 5,000 Liters | 1.25 kg | 800 LPH | HP 0.5, Volt 415, Phase 3, RPM 1450 | 900 x 500 x 500 |

| MFS/Four Filter | Up to 10,000 Liters | 1.25 kg | 1200 LPH | HP 0.75, Volt 415, Phase 3, RPM 1450 | 900 x 750 x 750 |

| MFS/Six Filter | Up to 15,000 Liters | 1.25 kg | 1800 LPH | HP 1.0, Volt 415, Phase 3, RPM 1450 | 900 x 750 x 750 |

| MFS/Eight Filter | Up to 20,000 Liters | 1.25 kg | 2400 LPH | HP 1.0, Volt 415, Phase 3, RPM 1450 | 900 x 1000 x 1000 |

All above data and technical specifications are subject to change based on specific application requirements and conditions.