Key Features

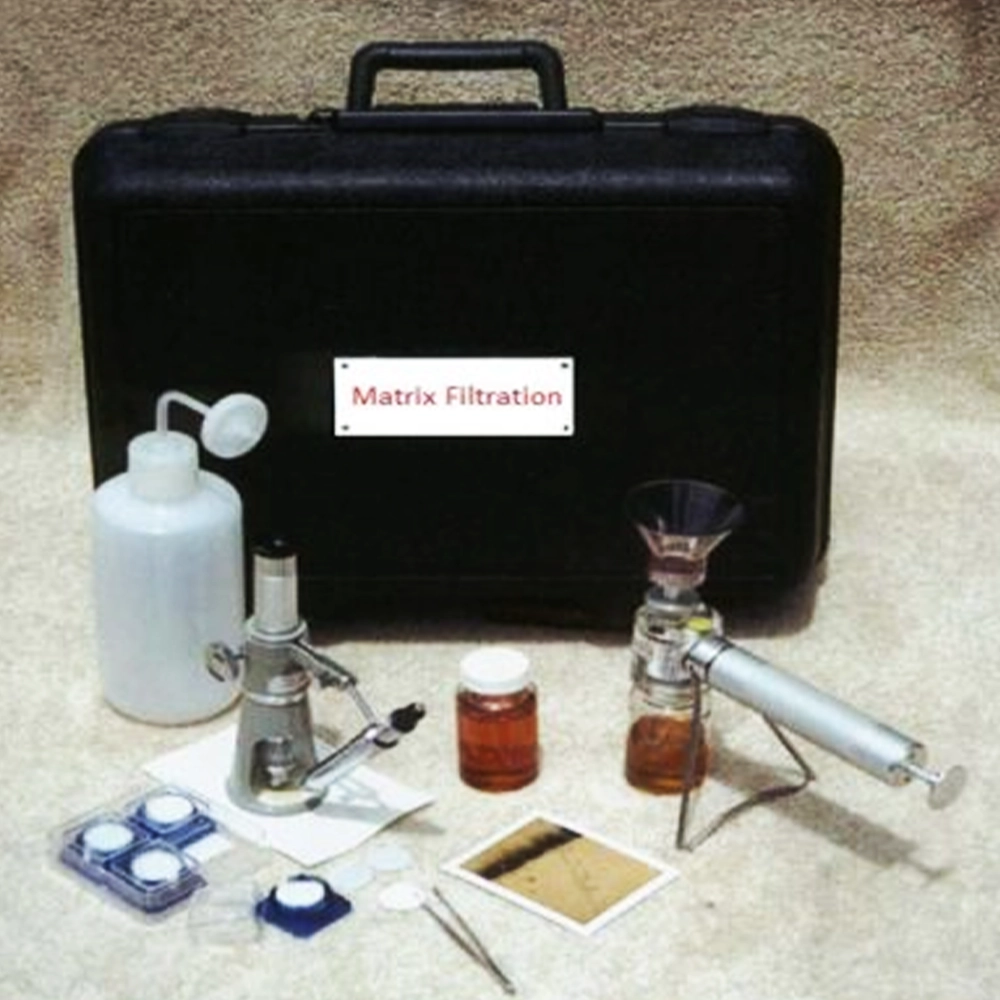

The Matrix Portable Oil Patch Test Kit is an indispensable tool for identifying and monitoring the contamination levels in oils such as hydraulic, lube, and turbine oils. This all-in-one kit enables instant visual analysis using a 100X microscope, making it easy to detect a wide range of contaminants—including metals, fibres, silica, plastics, and more—both before and after oil filtration.

The Matrix Portable Oil Patch Test Kit delivers a reliable, easy-to-use solution for monitoring oil quality, helping maintenance professionals and engineers ensure that their systems run efficiently with minimal contamination risks.

For further details on how this kit can enhance your maintenance regime, or to place an order, please contact us today.